Pallet Labelling

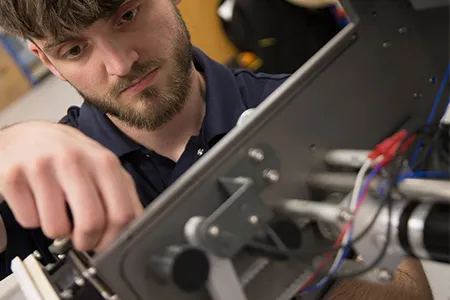

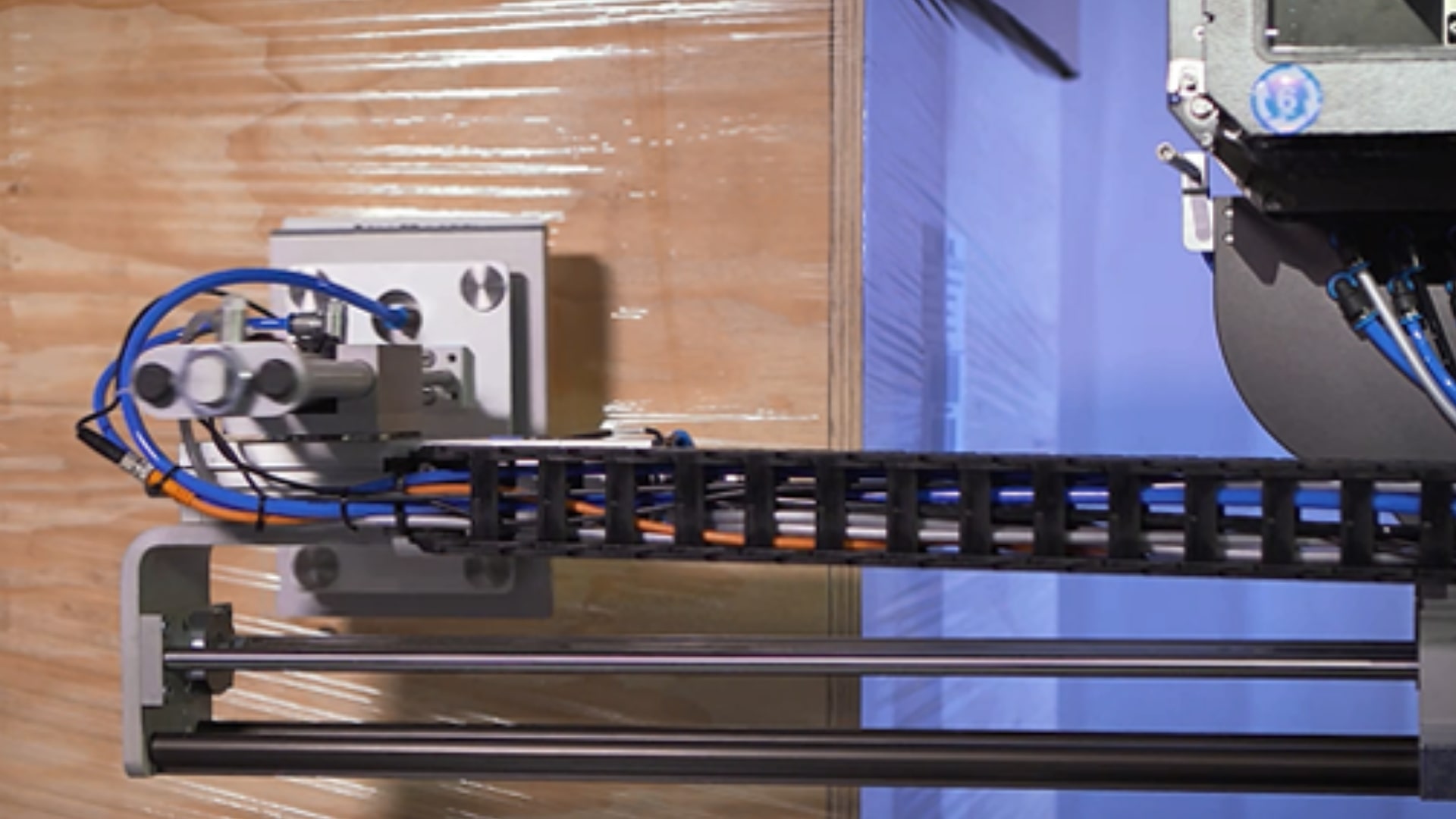

With an enviable track record in barcode labelling and a commitment to meeting GS1 global standards, we are the supplier of choice when it comes to pallet print and apply applications.

Whether it’s two or three-sided labelling required, the simplicity of our machine designs and optional Cobalt Sentinel Onboard software ensures all pallets are labelled correctly. Barcodes are verified, sequences validated, cases counted and receipted back into customer ERP systems, ensuring maximum uptime and minimal disruption to your operations.